GLASS FUSED TO STEEL TANKS

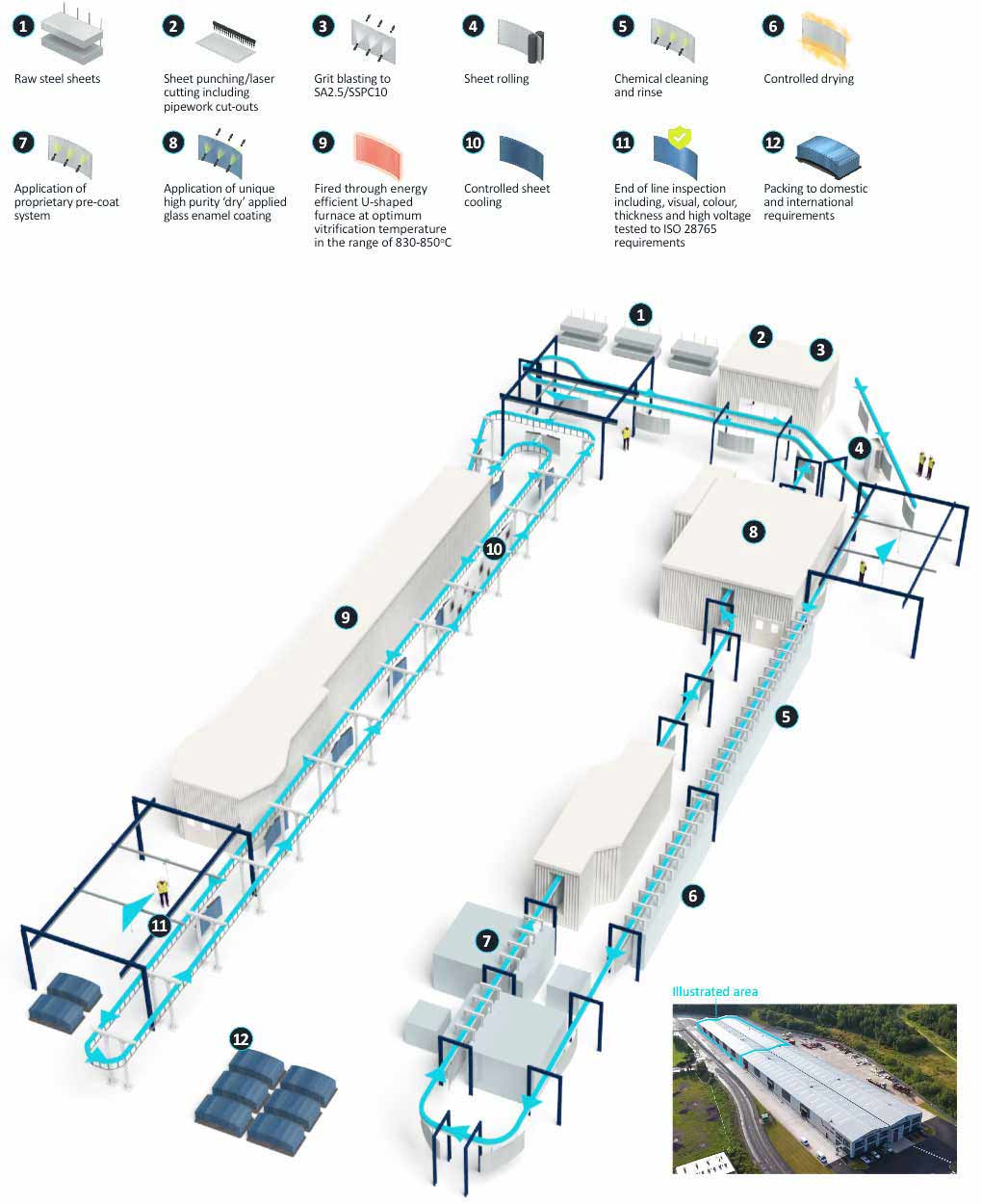

The term vitreous enamel comes from the word vitrification describing the transition of a substance into a glass. At typical vitreous enamel firing temperatures, usually in the range of 830-850°C, the coating reaches full mobility and viscosity.

During this period, interaction between the glass and steel accelerates, an interfacial adhesion layer is formed and synthesis of the two materials takes place.

Balmoral’s enamel system combines the strength of steel with the corrosion and scratch resistance of glass.

Compared to other spray application methods, which often use inorganic clays to suspend the particles in water, enamel powder coating provides the proven optimal purity. This technical advantage combined with Balmoral’s process represents a new level of excellence in glass fused to steel tanks and silos.

- Balmoral’s enamel system provides optimum purity

- Tough resilient coating

- A composite with the strength and flexibility of steel

- Chemically inactive coating and unaffected by UV light

Balmoral GFS tanks

Balmoral’s manufacturing process was designed to provide clients with a high performing, economical coating designed specifically for the containment of potable water and uncovered municipal wastewater tanks.

Balmoral GFS Premium

The Premium option was developed to deliver heightened performance and long-term value to asset owners and users around the world in more demanding applications.

Specification

| Balmoral product | Coating applications | EN ISO 28765 Group | pH resistance | Test voltage (V) | Thickness (µm) |

|---|---|---|---|---|---|

| GFS | 2 coat, 1 fire | 2 | 3-9 | 700 | 200-400 |

| GFS Premium | 3 coat, 2 fire | 3 | 2-11 | 1100 | 260-460 |

| GFS Premium Plus | 3 coat, 2 fire | 4 | 1-14 | 1500 | 340-500 |