Commentary - 27 May 2021

Automated 3D cylindrical tank design system provides quality improvements and cost savings

By Scott Franks

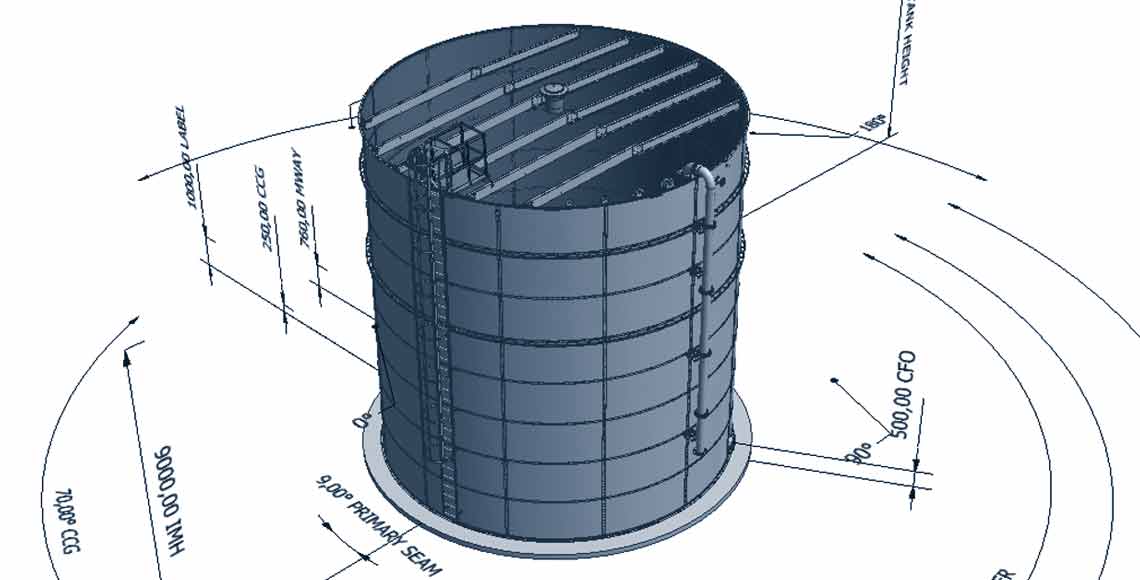

Significant investment in a new drawing process allows Balmoral to offer an unrivalled service, reducing time and improving quality while delivering on the company’s “right first-time” ethos.

The design team at Balmoral Tanks recently made the switch from 2D-based drawings to BIM-ready (Building Information Modelling) 3D drawings for cylindrical tanks. Adding value for clients at all stages of their project.

BIM models are offered to the client as well as traditional engineering drawings with the 3D models being used throughout the project to improve planning and execution of the build while eliminating costly errors.

For example, a cylindrical tank 3D model can be dropped into clients’ designs allowing visual checks for clashes and help plan external pipework in much greater detail than previously possible. This is also known as the “digital twin” concept, an accurate virtual representation of an object which can be used to plan, predict, monitor and analyse product or process data.

This is done by utilising a 3D “Master model” that offers numerous advantages for both internal and external customers. The new process allows for a 75% decrease in initial design time due to the significant investment the design team has made over the past few years in continuous improvement of their virtual library.

The 3D models are intelligently designed in CAD software to allow for quick and easy modification to a client’s specific needs. Designing the system in this way also speeds up any changes required by the customer; for example if a different component size is required, this can easily be done at the click of a button.

Installation teams will also benefit from the new process as communication is shared more visually than before. Information the installer needs is now depicted more clearly and adapted to suit the specific requirements for a particular project.

Future enhancements include sharing a “live” 3D model with the install team using specific BIM software and tablets allowing for a reduction in delays when sharing information on site. This will tie in with the design philosophy Balmoral is building upon, to share information in a more visual way to all clients.

Substantial investment at the front end means the department offers this solution today. All members of the Llantrisant-based design team have been involved, creating smart logic-based designs of all components needed to create the final product.

Specific BIM software means greater collaboration with the end user design team as it gives a common ground of communication, reducing the risk of error. Historically, separate systems or paper-based drawings were used to communicate the design of the product and did not allow for this.

The new process differentiates Balmoral in the market by significantly reducing the time required to complete a first issue drawing without compromising on quality.

The system also provides scope for instant client feedback. As the industry adapts to virtual meetings, Balmoral now uses video sharing platforms to discuss projects with clients and make changes on the fly, sharing live visual information on how the product will look. This reduces the number of revisions required which, in turn, gives the client a solution they need in a shorter period than was previously possible.

To discuss our new system further, or to see any examples, please feel free to contact the design team.

Example of drawings

Installed tank